Category

Pneumatic Vacuum Powder Particles Transport Xxnx Vacuum Conveyor Feeder Manufacturer

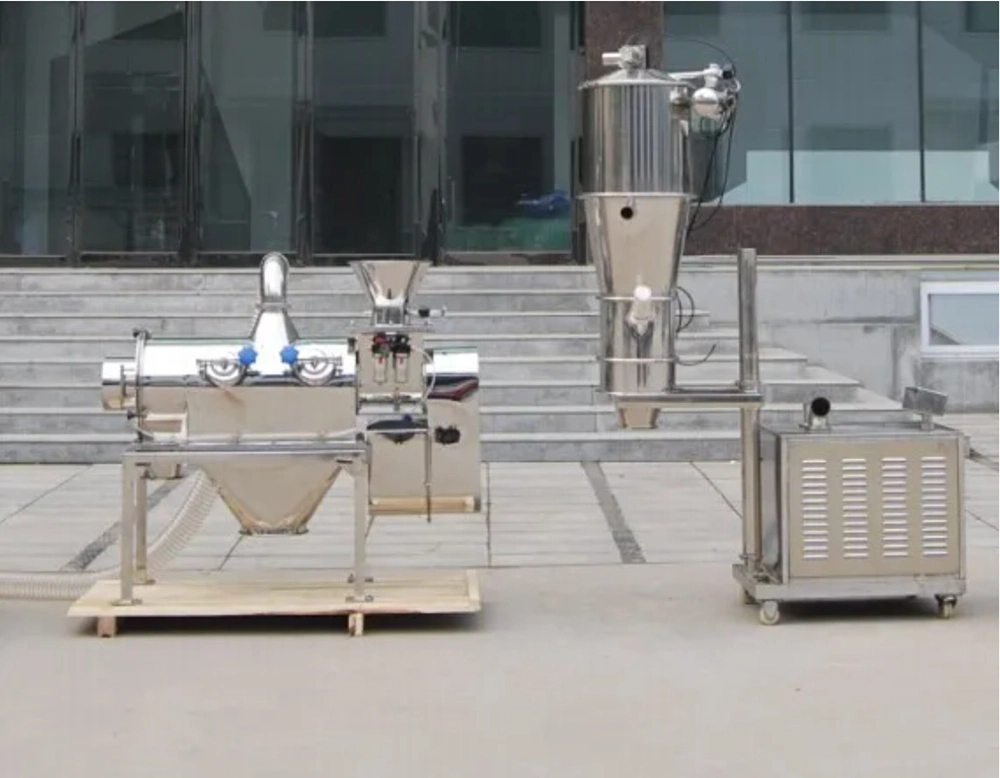

Overview Package Size 100.00cm * 120.00cm * 200.00cm Package Gross Weight 600.000kg Product Description ZKS Series Vacuu

Overview

Product introduction

The ZKS vacuum feeder uses a vacuum pump to pump air, so that the inlet of the suction nozzle and the whole system are in a certain vacuum state. The powder and particles are sucked into the nozzle along with the outside air to form a material air flow, and then reach the hopper through the suction pipe. Separation of gas and material in the middle. The separated material enters the receiving equipment. Conveying and discharging are accomplished through the continuous opening and closing of the pneumatic three-way valve, and the opening and closing of the pneumatic three-way valve is controlled by the control center.The ZKS vacuum feeder is equipped with a compressed air blowback device. Every time the material is discharged, the compressed air pulse blows back the filter to knock down the powder adsorbed on the surface of the filter, so that the suction can operate normally.Product advantages

Reduce environmental and personnel pollution to materials and improve cleanliness.

It occupies a small space, and can complete the powder conveying in a narrow space, making the working space beautiful and generous, not limited by the distance.

The entire conveying process is carried out in a closed system, and no powder leakage will occur.

Easy to visually inspect, the equipment has no gaps or dead corners that are easy to accumulate materials, and the surface is easy to visually inspect.

Reduce labor intensity and improve work efficiency.

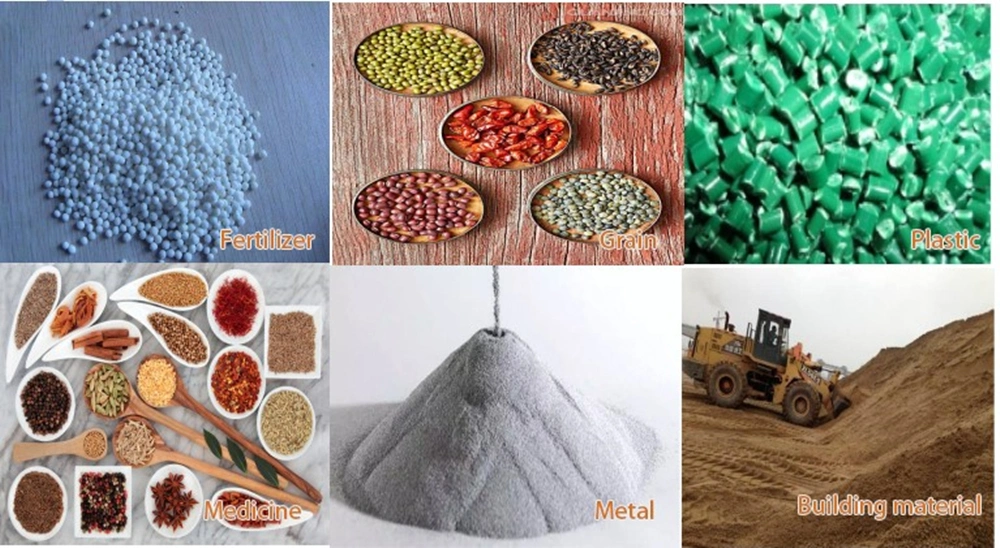

Scope of application

Medicine, food, chemical industry, metallurgy, building materials and other industries.

Application materials

various powder materials

Note:The data based on when the conveying distance is 4 meters and the materials is flour. The longer the conveying tube,the lower the capacity,the capacity also has relationship with the characteristic of conveying materials.

This machine can match with

1. bag dump station2. Centrifugal sifter

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Vibrating Screen Equipment, Crusher, Conveying Equipment, Mixer, Food Feeding And Screening System

4. why should you buy from us not from other suppliers?

Gaofu company founded in 1982, 20 years screening experience, the company covers an area of 50800 square meters.we posses the independent management right of importing and exporting, our products are spread all over the country, sold in faraway market area

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

Basic Info.

| Model NO. | ZKS-3 |

| Material | Carbon Steel or Stainless Steel |

| Material Feature | Other |

| Application | Chemical Industry, Grain Transport, Mining Transport |

| Condition | New |

| Feature | Easy Cleaning |

| Width or Diameter | 300mm |

| Core Components | Motor |

| After-Sales Service Provided | Video Technical Support |

| Capacity | by Model |

| Materia | Stainless Steel |

| Power | 1.5-11kw |

| Advantage | Improve Work Efficiency |

| Product Name | Vacuum Feeder |

| Transport Package | Wooden Box |

| Specification | as per model |

| Trademark | Gaofu |

| Origin | Henan, China |

| Production Capacity | 10000set/Year |

Packaging & Delivery

Package Size 100.00cm * 120.00cm * 200.00cm Package Gross Weight 600.000kgProduct Description

Product Description

ZKS Series Vacuum Feeding MachineProduct introduction

The ZKS vacuum feeder uses a vacuum pump to pump air, so that the inlet of the suction nozzle and the whole system are in a certain vacuum state. The powder and particles are sucked into the nozzle along with the outside air to form a material air flow, and then reach the hopper through the suction pipe. Separation of gas and material in the middle. The separated material enters the receiving equipment. Conveying and discharging are accomplished through the continuous opening and closing of the pneumatic three-way valve, and the opening and closing of the pneumatic three-way valve is controlled by the control center.The ZKS vacuum feeder is equipped with a compressed air blowback device. Every time the material is discharged, the compressed air pulse blows back the filter to knock down the powder adsorbed on the surface of the filter, so that the suction can operate normally.Product advantages

Reduce environmental and personnel pollution to materials and improve cleanliness.

It occupies a small space, and can complete the powder conveying in a narrow space, making the working space beautiful and generous, not limited by the distance.

The entire conveying process is carried out in a closed system, and no powder leakage will occur.

Easy to visually inspect, the equipment has no gaps or dead corners that are easy to accumulate materials, and the surface is easy to visually inspect.

Reduce labor intensity and improve work efficiency.

Scope of application

Medicine, food, chemical industry, metallurgy, building materials and other industries.

Application materials

various powder materials

Product Parameters

| Model | Motor power (kW) | Delivery capacity (kg/h) |

| ZKS-1 | 1.5 | 400 |

| ZKS-2 | 2.2 | 600 |

| ZKS-3 | 3 | 1200 |

| ZKS-4 | 5.5 | 2500 |

| ZKS-6 | 5.5 | 3200 |

| ZKS-7 | 7.5 | 6000 |

| ZKS-10-6 | 7.5 | 6000(when the conveying distance is 10 meters) |

| ZKS-20-5 | 11 | 5000(when the conveying distance is 20 meters) |

This machine can match with

1. bag dump station2. Centrifugal sifter

Packaging & Shipping

Recommended Featured

Certifications

Company Profile

Xinxiang Gaofu Machinery Co., Ltd. specializes in manufacturing vibration screens and vibrating sieves. To solve sieving problems in all fields, we can manufacture all kinds of vibrating screens to meet the different needs of customers. Thanks to production equipment, strong technical capabilities, improved detection means and strict managing system, we have enjoyed good reputation. our company has attained ISO9001:2000 certification and CE Certification. Our products sell well throughout China and are exported to North America, West Europe, Southeast Asia and other countries and regions. Do you want to improve your product quality? Do you want your products to become more competitive? Choosing Xinxiang Gaofu Machinery Co., Ltd.! We will be your friend in the way to success! And you will create a shiny future in 2017! Please visit our website: www.gaoful.com. Our tenet: "Honest Service, the Highest Quality".To solve sieving problems in all fields, we can manufacture all kinds of vibrating screens to meet the different needs of customers.FAQ

1. who are we?

We are based in Henan, China, start from 2000,sell to Southeast Asia(40.00%),Domestic Market(27.00%),South America(10.00%),Eastern Europe(8.00%),Oceania(3.00%),North America(2.00%),Western Europe(2.00%),Africa(2.00%),South Asia(1.00%),Eastern Asia(1.00%),Southern Europe(1.00%),Central America(1.00%),Northern Europe(1.00%),Mid East(1.00%). There are total about 301-500 people in our office.2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Vibrating Screen Equipment, Crusher, Conveying Equipment, Mixer, Food Feeding And Screening System

4. why should you buy from us not from other suppliers?

Gaofu company founded in 1982, 20 years screening experience, the company covers an area of 50800 square meters.we posses the independent management right of importing and exporting, our products are spread all over the country, sold in faraway market area

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA;

Accepted Payment Currency:USD,EUR,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese

Contact Us

Tell me the following questions, Then I can send you accurate quotation soon, including additional discount!Your email addressand telephone will not be shared or published!The proper selection of the vibrating screen depends on the material, mesh size,output required, method of input,abrasiveness of the material etc:1. Screening product : _____2. Moisture:_____%3. Capacity:________kg/ hour4. Screen layer:_______5. Screen mesh size:______ mesh . ______ mesh. ______ mesh6. Voltage:______V,Frequency:______HZ, 3 phase7. SS304/316L stainless steel or Q235A carbon steel?