Steel Wire Bar Straighter 8mm 10mm 12mm 14mm 16mm Rebar Straightening and Cutting Machine

Basic Info.

| Model NO. | YGTQ4-10 |

| Voltage | 380V |

| Automatic Grade | Automatic |

| Principle | Small Deformation |

| Certification | TUV, CCC, ISO9001, CE |

| Warranty | 12 Months |

| Customized | Customized |

| Condition | New |

| Pulling Motor(Kw) | 7.5 |

| Machine Weight(Kg) | 360 |

| Straighten Speed(M/Min) | 35-45 |

| Cutting Length(mm) | 200-8000 |

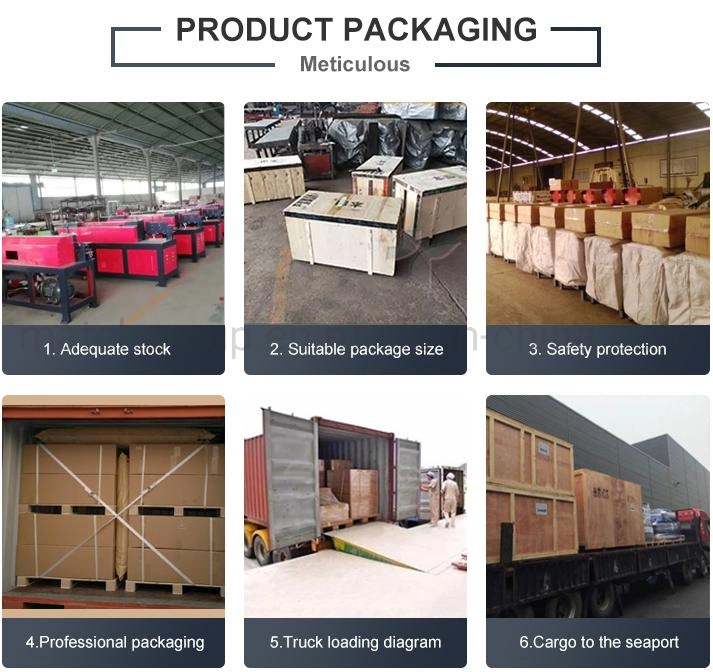

| Transport Package | Wooden Case |

| Specification | 1.4*0.65*0.75 |

| Trademark | Match |

| Origin | Shandong, China |

| Production Capacity | 10sets/Week |

Product Description

CNC Hydraulic Wire Rod Straightening And Cutting Machine

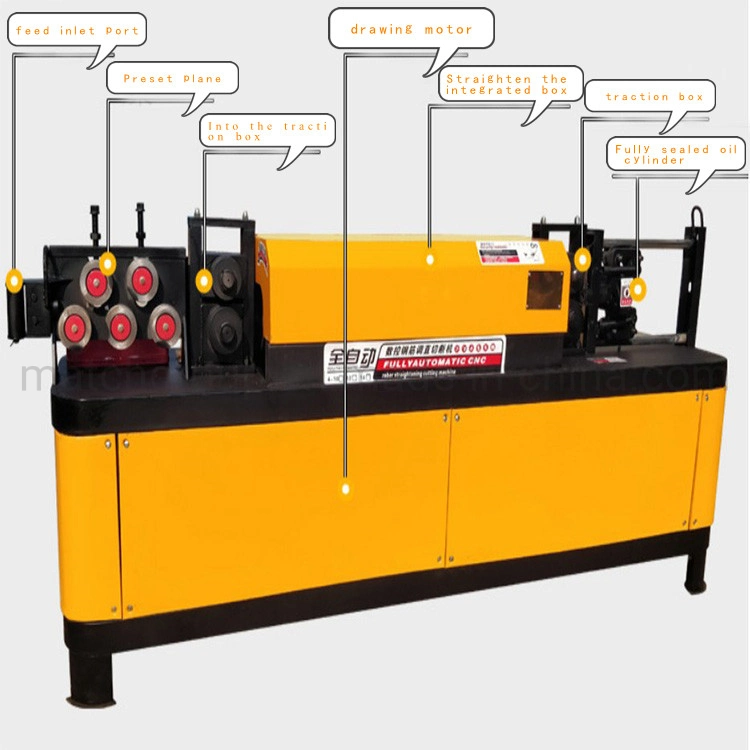

1. YGTQ Series automatic wire straightening and cutting machine is a kind of highly effective equipment, it has the following features:

1) Speed can be adjusted

2) Straightening fast without distortion 3) High yield and low consumption 4) No hurt to the ribs, stably running, small cutting errors, 5) Low failure rate: work with high performance for a lone time under normal condition debugging.

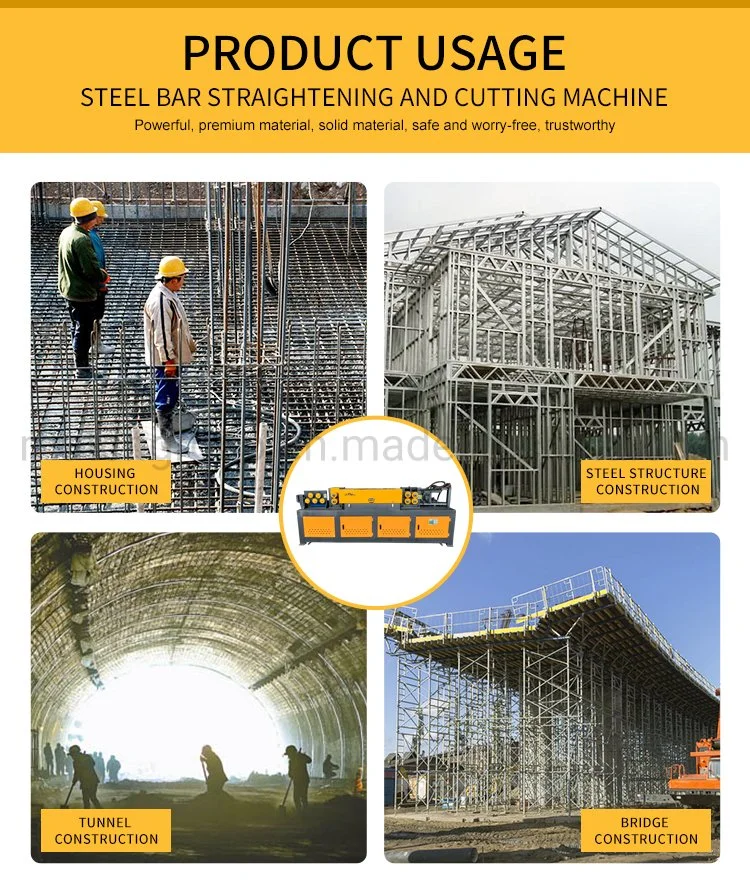

This automatic wire straightening and cutting machine is efficient for cutting steel bars on project. It can cut different kinds of round steel bar and deformed steel bar. It's made of high steel knife seat and connecting shaft, international standard high speed motor and firm reinforcing covering. The machine is very small, solid, self-lubrication, little power loss; easy operation and easy moving with four wheels and the knife can be manually controlled.

2. Technical parameter of wire straightening and cutting machine

Model Number | YGTQ4-10 | YGTQ4-12(1) | YGTQ4-12(2) | YGTQ5-14 | YGTQ6-16 |

Round steel bar(mm) | φ 4-φ 10 | φ 4-φ 12 | φ 4-φ 12 | φ 5-φ 14 | φ 6-φ 18 |

Deformed steel bar(mm) | φ 4-φ 8 | φ 4-φ 10 | φ 4-φ 10 | φ 5-φ 12 | φ 6-φ 16 |

Cutting length(mm) | 200-8000 | 300-8400 | 300-8400 | 300-8400 | 300-9500 |

Cutting error(mm) | ±10 | ±10 | ±10 | ±10 | ±10 |

Straighten speed(m/min) | 35-45 | 40-45 | 40-45 | 50-55 | 60-80 |

Straighten motor(kw) | / | / | / | / | / |

Pulling motor(kw) | 7.5 | 7.5 | 7.5 | 11 | 15 |

Cutting motor(kw) | / | 5.5 | / | 5.5 | 5.5 |

L*W*H(m) | 1.4*0.65*0.75 | 2.0×0.64×1.3 | 1.9×0.84×0.9 | 2.9×0.64×1.3 | 4.0×6.5×1.2 |

Machine weight(kg) | 360 | 900 | 650 | 1200 | 1500 |