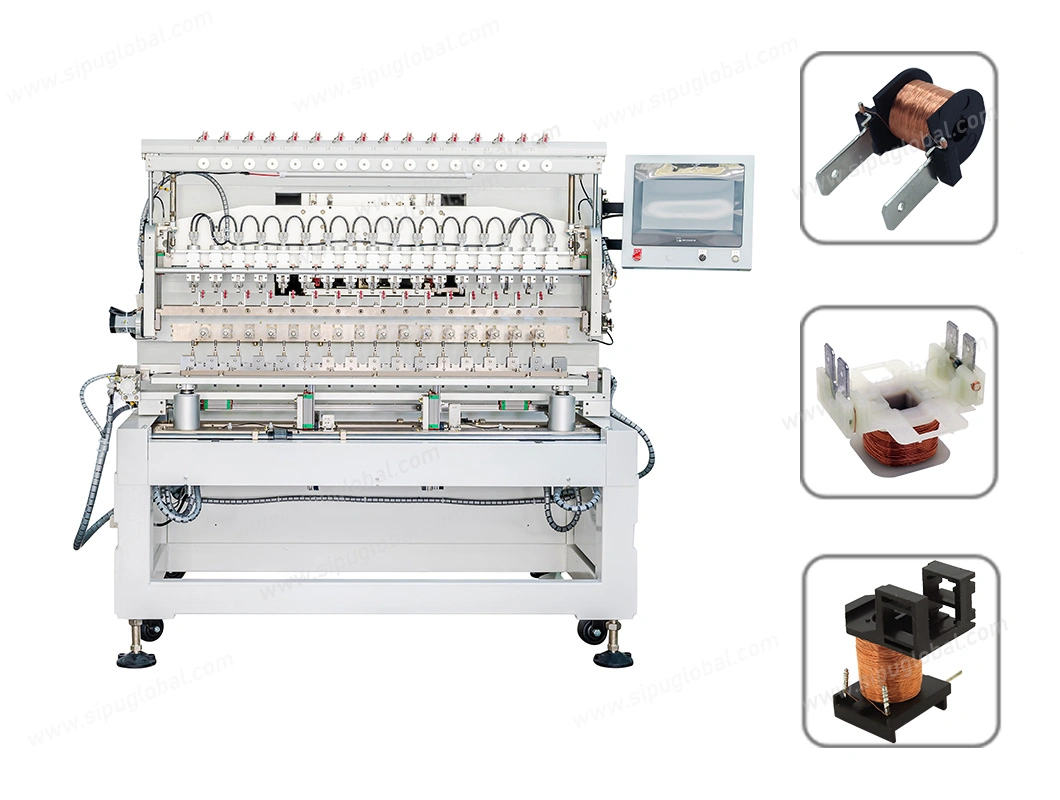

16 Axis High Precision CNC Automatic Relay Bobbin Coil Winding Machine

Basic Info.

| Manufacture Solenoid | Use Sipu′s Solenoid Coils Winding Machine |

| Traverse Moving Range | X:110, Y:110, Z:80 |

| Spindle Speed | Max.18000rpm (Cw/Ccw) |

| Produce Relay | Use Sipu′s Relay Winding Machine |

| No. of Spindle | 16 Spindles |

| Condition | New |

| Automatic | Automatic |

| Transport Package | Wooden Box |

| Specification | 1300(W)× 1250(D)× 1270(H)mm |

| Trademark | SIPU |

| Origin | China |

| HS Code | 8479811000 |

| Production Capacity | 600 Set / Years |

Product Description

Product Description16 Axis High Precision CNC Automatic Relay Bobbin Coil Winding Machine

Detailed Photos

Product Description

16 spindles CNC Precision Automatic coil Winding Machine

Description :

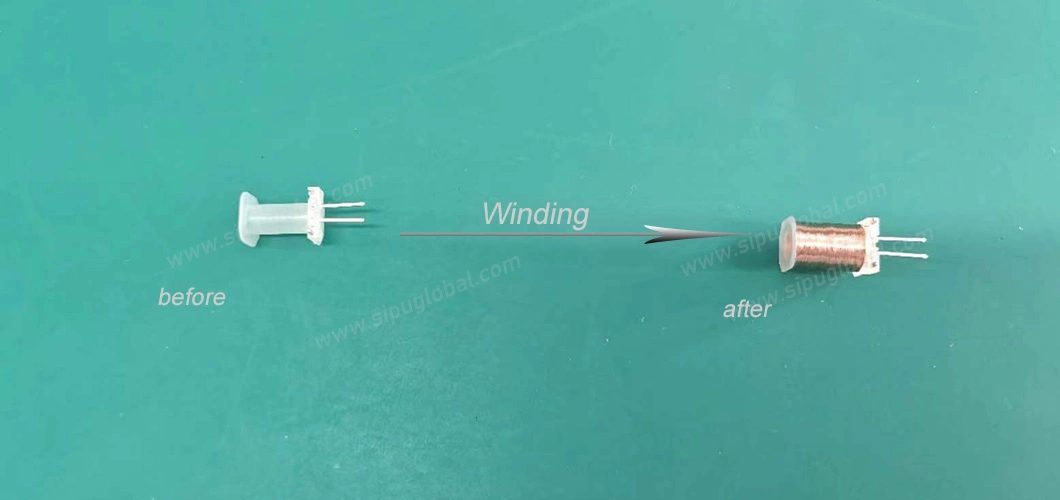

The coil winding equipment is a powerful and efficient solution for all your coil winding needs. With 16 spindles and the ability to wind in multiple directions and angles, this multi-axis winding machine is perfect for layer winding.With precise tension control and the ability to create a range of coil types, including bobbin coils, our machine is suitable for a wide range of applications, from automotive to industrial,such as relays, current contactors, solenoid coils, inductor coil, filter choke coil,lens coil, transformer coil, inverter coil, valve coil, ignition coil, adapter coil, switch coil,car horn coil, primary coil, mirror coil and various related coil etc.

The winding machine is highly automated, efficient, and can be programmed to wind coils of different sizes and shapes. This ensures fast, precise, and consistent coil winding, which is critical for ensuring the performance and reliability of the final product.

Machine Features:

1.Advanced CNC control technology for easy programming and operation

2.Intuitive touch screen interface for setting winding speed, turns, and direction

3.Safety features that automatically stop the machine in case of malfunction

4.16-axis winding machine with 60mm shaft spacing, suitable for medium-sized frame winding processes

5.Quick-change fixture structure for easy replacement of winding fixtures

6.Winding shaft equipped with high-speed bearings, achieving a maximum speed of 18,000 RPM

7.S3M wear-resistant synchronous belt to reduce noise

8.Electrically designed with servo motors to reduce air consumption and provide higher programmability and smoother mechanical movements.

Specification of each moedel :

| Model | SPBZ23-A1B16 |

| No. of Spindle | 16 Spindles |

| Spindle Pitch(mm) | 60mm |

| Spindle Speed(rpm) | Max.18000rpm (CW/CCW) |

Maximum Travel Distance | X-Axis 110mm (Front/Back) |

| Y-Axis 110mm (Left/Right) | |

| Z-Axis 80mm (Up/Down) | |

| Controller | EtherCAT or RTEX controller |

| Wire Range(mm) | 0.02-0.4mm |

| Power Source | AC380V 3P 50HZ or AC200V 3P 50/60HZ |

| Power Consumption | 2000W |

| Air Pressure (Mpa) | 0.4Mpa~0.6Mpa |

| Machine Size (mm) | 1300(W)×1250(D)×1270(H)mm |

| Machine Weight (mm) | About 1100KG |

Option | 1.Wire twister |

| 2.Cutter | |

| 3.Automatic loading & unloading | |

| 4.Peeling device | |

| 5.Electrical tensioner |

Production Workshop

Certifications

Packaging & Shipping